Wow! And just like that, Build Season and our competition passed by in the blink of an eye! Let's look back at the past few months and look forward to the off-season.

Game Description

It seems like just yesterday, team 4930, the Electric Mayhem, was hosting us at their school to participate in a shared game reveal and kickoff. Students and mentors alike gathered to watch the live stream, where we waited patiently for the game video to be shown for the first time.

And then we received the FIRST CHARGED UP game video...watch it below!

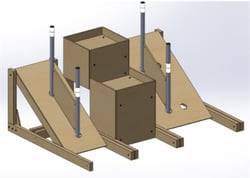

The robot was challenged to collect plastic cones and inflatable cubes from around the arena and then score them in the "Grid". The picture here shows a small section of the Grid, where the cones are placed on the pipes, and the cubes are laid in flat sections. Different height levels provided varying degrees of difficulty and points scored.

The robot was challenged to collect plastic cones and inflatable cubes from around the arena and then score them in the "Grid". The picture here shows a small section of the Grid, where the cones are placed on the pipes, and the cubes are laid in flat sections. Different height levels provided varying degrees of difficulty and points scored.

The first fifteen seconds of the match are autonomous, where the robots move without user input. Any actions done during "auto" would net a team more points than usual. The last thirty seconds - called the end game - challenged the teams to balance one to three robots on a teeter-totter to score extra points if they were balanced.

Build Season

The robot must be designed and built from scratch in the six to eight weeks between the game reveal and our competition, so we had to be creative and resourceful with our resources and task management. Many teams start the season by brainstorming ideas and sketching designs on whiteboards, and we were no different. There's a lot to consider about the game objectives and constraints - such as what scores the most points or has the faster "scoring cycle times" - as well as our own team's strengths and weaknesses.

The biggest 'elephant in the room' this year was our experience. The Alumiboti had a few returning mentors who had built an FRC robot before, but we were almost fully new mentors and a new team - 90% of who were freshmen! This situation meant we had a lot of adversity and steep learning curves to overcome while developing our strategies and design.

The biggest 'elephant in the room' this year was our experience. The Alumiboti had a few returning mentors who had built an FRC robot before, but we were almost fully new mentors and a new team - 90% of who were freshmen! This situation meant we had a lot of adversity and steep learning curves to overcome while developing our strategies and design.

We spent long hours in the lab, tweaking and adjusting our designs until we achieved the desired performance. This process of brainstorming, designing, prototyping, testing, and refining is one of FIRST's greatest strengths because it teaches real engineering trade-offs in a low-risk, safe environment. It provides students with the opportunity to learn valuable skills in engineering, programming, and teamwork. It's a chance for students to work together, overcome challenges, and create something truly amazing.

On top of our Tank Drive chassis, our robot was built using four "subsystems" - aka modular components that work together:

- A Ground Instake system that was responsible for vacuuming up the cones and cubes from the floor in different orientations

- A Grabber Claw that used pneumatics to grab and release game pieces collected from the intake.

- A Telescoping Arm that allowed the Grabber to extend in-and-out to different collection and scoring positions.

- A Shoulder pivot that raised and lowered the arm to reach different heights and configurations.

Check out the images below. These did come from post-competition, so you will notice that we added a covering over the ground intake. During the final matches, we focused solely on the Ground scoring, which was previously open and allowed the game pieces to enter into the robot for the Grabber and Arm assembly to manipulate.

Finger Lakes Regional Competition

The Alumiboti attended the Week 3 Finger Lakes Regional competition at the Rochester Institute of Technology. It was our first full competition since 2019 - although we drove there in 2020 before promptly being told to turn around since it was the weekend COVID-19 shut the world down.

We didn't finish some of the position controls of the shoulder and arm assemblies until the Tuesday before, so while most teams loaded in Wednesday evening, we elected to drive up Thursday morning, which allowed Wednesday to be all focused on drive practice, where we let the students get used to the robot.

Thursday morning came, and our groggy students and mentors showed up early at St. Joe's to depart at 7 am, and we arrived at 8:15 am and promptly began setting up our pits and getting our robot for inspection.

Thursday morning came, and our groggy students and mentors showed up early at St. Joe's to depart at 7 am, and we arrived at 8:15 am and promptly began setting up our pits and getting our robot for inspection.

If you've never been in the pits of a FIRST Robotics Competition before, then let me tell you; it's part chaos, part excitement, and all fun. Students are going pit to pit asking about others' robots, the crews are frantically checking every last bolt, connector, and wire to ensure it's good to go.

Thursday hosts the practice matches, where teams calibrate their autonomous mode(s), drivers see what they are capable of, and individual team strategies begin to arise. We started fairly strong with a focus on driver training since both operators were freshmen with almost no experience. They were able to quickly put up points and maneuver the robot as needed to be as effective as we could with our setup. As the day progressed, we finalized our autonomous strategy of depositing a cube and leaving the community, scoring points for both actions. It wasn't the fanciest, but it worked consistently, and that's all we could ask of for an almost-Rookie team like ours.

Friday saw the beginnings of Qualification matches, where randomly selected alliances (aka teams of three vs three) face each other to determine a ranking. The Alumiboti were able to start the morning with a really great 2-1 start, but then luck had other plans. We had a match where our alliance partners tipped over, leaving us to be the only point scorers, and another match where none of the three alliance partners could perform their "usually reliable" tasks.

We finished qualifications 4-5-0, but we could have been 6-3-0, had a few minor "luck moments" or situations gone the other way. Ultimately, we were ranked 33rd out of 55 teams and were not selected for Playoffs, but that's okay; the competition was already a success for us! We were essentially a fully-rookie team with almost all freshmen, having returned from a few years off in a robotics competition where a lot had changed. We are excited by the successes we experienced, will build off the mistakes and situations that didn't go our way, and our team has an incredibly high ceiling for the next few years (just look at our "What Next?" section below!)

The mentors could not have asked for more from the students or themselves, given the circumstances, and the Alumiboti are really excited about what we did, where we are right now, and where we are going next!

What Next?

The team plans on participating in a wide range of projects during the off-season to help develop new skills, expand our knowledge of robotics, and strengthen our teamwork abilities.

First off, we want to unwind and have some fun after a stressful Build Season, so we are trying to plan a day for our team members' families to come to the shop for dinner and to see what we built! This will be a great way for students to show off what skills they've learned through robotics, and the real accomplishments they've achieved with their hard work! We also plan on having a team bonding activity or two, which paintball has already been brought up, but let's see if the mentors are up for that. 🫣

In terms of real projects to keep our minds sharp and team competitive, we have a few ideas (and these are in no particular order):

- Outreach and Community Service: We would love to engage with our community more! This involves volunteering with organizations, promoting STEM to other groups, and collaborating with other teams. This is probably the vaguest goal, but we'll start planning our actions soon, so stay tuned!

- Computer-Aided Design (CAD) Lessons: The Alumiboti built a robot this year that worked, so woohoo! 🎉 But it almost didn't happen because of the mechanical limits we ran into while assembling and testing the robot. Next year, we plan on having a CAD-first Approach to building the robot, meaning we will sketch our designs and the final robot using CAD software, such as OnShape, before building the final pieces. This will ensure that our dimensions are valid, our torque and gear ratios are optimized, and our robot works a lot smoother a lot sooner, rather than having to make adjustments the day before the competition. We plan on teaching students and mentors how to use CAD to design and build the robot, and expect it to provide great returns during the Build Season!

- Swerve Drive: Back in 2020, FIRST announced that they were getting rid of the $5000 limit on the Bill of Materials, and it turns out that made people very happy. A few years later, though, it seems as though every established team - and even some ambitious rookies - have migrated towards "swerve drive" chassis drivetrains, which allow all four wheels to move and rotate independently of one another. They are a financial headache and a programming nightmare, but the Alumiboti are ready for the challenge and hope to get a lot of testing of a swerve drive base in the off-season!

- Funding Round(s) for a CNC Router: Along with Swerve Drive, another thing that separates the premier teams from the average ones is the addition of a CNC Router or Mill to their machining shop. The ability to quickly and repeatably machine parts from CAD files cuts manufacturing time down from a few hours or days to only a few minutes. It allows teams to increase their output and manufacture higher-quality pieces that can be done by hand in a fraction of the time. We plan on creating a few sponsorship and fundraising campaigns to work towards getting a CNC Router because of the upsides mentioned, but they are not cheap. If you want to help, please visit our Donation page and consider giving!